Water Injections in GC: Is it Safe?

October 17, 2025

Reviewed by Duilio Romanello

Injecting water into a gas chromatography (GC) system has always raised concerns for analysts. Many wonder if water will damage their GC column or instrument. In fact, one of the most common questions in gas chromatography water analysis is whether aqueous samples can be safely introduced without compromising results.

Selecting the right GC column for water analysis and following proper injection techniques can minimize the risk of column damage and maintain reliable analytical results.

Why Water Injections Are Risky in GC

Water injections in gas chromatography columns are risky due to the following reasons:

Backflash Issues

Water expands significantly when vaporized at high inlet temperatures (e.g., 250–300 °C). If the expansion volume exceeds the inlet liner capacity, backflash can occur. This contaminates injector parts, leaving residues that cause ghost peaks, carryover, sample loss, and elevated baselines, ultimately reducing reproducibility and accuracy.

Stationary Phase Degradation

As a highly polar solvent, water can hydrogen bond with stationary phase polymers such as polyethylene glycol (PEG) or wax phases. Repeated exposure alters selectivity, shifts retention times, and may increase bleed in non-crosslinked phases. While older immobilized PEG phases are especially vulnerable, modern chemically bonded and crosslinked stationary phases offer improved resistance, making them more suitable to inject up to 100% water samples.

Incomplete Vaporization

Water’s high boiling point and poor wetting of non-polar stationary phases can result in incomplete vaporization. This may lead to peak splitting, band broadening, or reduced sensitivity. For this reason, injection settings need to be finely adjusted to avoid these effects.

Detector Issue

Standard GC detectors do not directly detect water. Excess water injected into a flame ionization detector (FID) can quench or even extinguish the flame, while moisture in an electron capture detector (ECD) can interfere with electron capture efficiency, suppressing signals or causing false responses.

Choosing the Right GC Columns for Water-Containing Samples

Here are some strategies that can help you increase the life of GC columns when analyzing water-containing samples.

- Use of cross-linked phases: Modern stationary phase design has greatly improved tolerance to water injections in GC. Cross-linking chemically bonds the stationary phase to the silica surface, making it far more resistant to leaching or washout from polar solvents. Traditionally immobilized but not cross-linked phases were much more vulnerable to degradation. For example, polyethylene glycol (PEG) phases are inherently hydrophilic and prone to water damage unless cross-linked. With technologies such as engineered self-crosslinking (ESC), used in Phenomenex Zebron ZB-WAXplus GC columns, PEG phases can withstand repeated water injections without significant loss of efficiency.

- Use of non-polar columns: Non-polar bonded and cross-linked columns (e.g., PDMS phases) are inherently resistant to water damage, though incomplete vaporization may still affect peak quality.

Tips to Protect Your GC System from Water Damage

Implementing a few key tips can help protect your GC system from water damage. Here are some of the important recommendations:

- Keep injections small: Limit water injections to ≤0.2 µL to minimize backflash and protect the stationary phase.

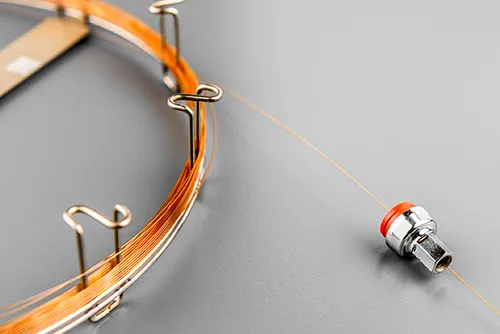

- Select the right liner: Use an appropriately sized inlet liner (e.g., 4.0 mm ID tapered or with a double gooseneck) to reduce backflash. A deactivated glass wool plug can promote rapid vaporization, though it may not be suitable for all analytes.

- Reduce syringe carryover: Rinse syringes with a 50:50 methanol–water mixture between injections. In some methods, preparing samples with a small percentage of methanol can improve reproducibility and syringe performance.

- Optimize solvent and injector conditions: Limit water injections to ≤0.2 µL to minimize backflash and protect the stationary phase.

- Adjust carrier gas conditions: Ensure your gas chromatography injector setup is correct to prevent water buildup. Combining water with a lower-expansion solvent (e.g., methanol) and maintaining an optimized injector temperature helps improve vaporization while limiting expansion.

- Maintain a clean carrier gas supply: Replace gas cylinders before they are nearly empty to avoid backflow or moisture intrusion into the system

While injecting water into a GC system is not simple and ideal, it can be managed safely with the right precautions. By choosing the appropriate stationary phase, following proper GC injector setup, and maintaining your instrument, you can conduct gas chromatography water analysis with confidence. For more information on GC hardware and maintenance, explore the key parts of a GC instrument.

FAQs

Can you inject water directly into a GC system?

Direct injections of water are generally discouraged. However, when using a GC column for water analysis designed for polar solvents, small volumes can be tolerated under controlled conditions.

What happens if water enters the GC column?

Water can swell traditional PEG stationary phases, hydrolyze bonded coatings, and cause peak distortion. These water injection problems often manifest as tailing peaks, unstable baselines, or shortened column lifespan.

Are there GC columns that can handle water injections?

Yes, modern GC columns with cross-linked stationary phases, such as PDMS or PEG columns using engineered self-cross-linkage (ESC) technology, can handle water injections in GC. Non-polar bonded and cross-linked columns also tolerate water without performance loss. Additionally, water-tolerant columns, like the Zebron ZB-WAXPlus, are specifically designed for aqueous samples and maintain efficiency even after repeated water injections.