Maintenance and Troubleshooting of GC Columns

August 26, 2025

Reviewed by Our Phenomenex Team

Gas chromatography (GC) is a widely used analytical technique across industries for separating and analyzing complex mixtures. Even with premium equipment and optimized methods, analytical problems can emerge. Many laboratories encounter issues such as peak tailing, resolution loss, or signal degradation without a systematic approach for diagnosing them. These problems frequently originate from a critical component: the GC column.

Proper column maintenance and troubleshooting skills are essential for ensuring accurate data and consistent analytical runs. GC troubleshooting guide provides actionable solutions to common gas chromatography problems, serving as a comprehensive resource to help minimize downtime and maintain analytical quality.

Common GC Column Issues and What They Mean?

The GC column plays a central role in chromatographic separation. When the column issues arise, data integrity is often compromised. Understanding the common problems is the first step in effective troubleshooting in gas chromatography.

Peak Tailing

Peak tailing occurs when chromatographic peaks lose symmetry and gradually extend toward the baseline. This phenomenon typically arises due to:

- Active sites within the system (residual silanol groups)

- Insufficiently deactivated inlet liners

- Column overloading

Tailing hinders quantitation accuracy and reduces separation efficiency between closely eluting analytes. Remedial steps include trimming the column inlet, replacing liners, or adjusting the sample load.

Loss of Resolution

Poor separation between adjacent peaks, often resulting in partial or complete peak overlap, indicates resolution loss. Common causes include:

- Column aging

- Suboptimal temperature programming

- Inadequate carrier gas flow rates

When resolution decreases, reliable analyte identification becomes challenging. Adjustments to temperature gradient and carrier gas pressure may help restore performance; if improvements are not observed, trimming or replacing the column may be necessary.

Ghost Peaks

Ghost peaks are unexpected signals that appear even during blank injections. These anomalies typically result from system contamination, septum bleed, or sample carryover from previous analyses. They can compromise data integrity and mask true analyte peaks.

Effective mitigation includes replacing the septum, thoroughly cleaning or replacing inlet liners, and confirming solvent purity. A clean system should yield no peaks during a blank run.

Baseline Noise or Drift

Unstable baselines can obscure low-level signals and reduce signal-to-noise ratios.

Potential causes include detector instability, leaks, or the use of impure carrier gases.

Resolution involves leak detection, maintenance or replacement of detector components, and ensuring the use of ultra-high purity gases equipped with appropriate moisture and hydrocarbon traps.

Decreased Sensitivity

Diminished detector response, particularly for trace-level analytes, indicates sensitivity issues. This issue often stems from inlet contamination, detector fouling, or degradation of the column. Maintenance actions should include cleaning or replacing the inlet liner, inspecting the detector, and running a performance test mix.

Retention Time Shifts

Inconsistent elution times lead to unreliable analyte identification. Shifts can result from unstable oven temperatures, fluctuations in carrier gas flow, or pressure inconsistencies.

Troubleshooting involves verifying temperature program stability, inspecting leaks and confirming flow rates with a calibrated flow meter. These issues are widely recognized in chromatographic literature and underscore the importance of proactive monitoring and maintenance to uphold system performance and data quality.

A Step-by-Step GC Troubleshooting Guide

The following troubleshooting process can reduce both time and unnecessary expenses. The five-step guide below outlines a systematic approach to isolating and resolving common gas chromatography issues.

Step 1: Evaluate Recent Methods or Hardware Modifications

Operational issues frequently follow changes in method parameters or instrument configuration. Alterations such as switching columns, adjusting injection conditions, or modifying the temperature program can introduce new variables.

Recommended action: Review recent updates to the method or instrument setup. Reverting to a previous configuration may quickly resolve the problem.

Step 2: Examine the Inlet and Detector Conditions

Contamination is a leading cause of chromatographic anomalies. Accumulation of particles from degraded septa, residues in inlet liners, or buildup within the detector can negatively impact peak shape and baseline stability.

Recommended action: Inspect the septum, inlet liner, and detector for contamination or wear. Perform routine cleaning and replace parts as needed to maintain system integrity.

Step 3: Inspect Column Installation and Physical Condition

Incorrect column installation may result in leaks or dead volume, while non-volatile materials often accumulate at the inlet end over time.

Recommended action: Check both ends of the column for signs of discoloration or damage. Trim 10–30 cm from the inlet if residue is visible and confirm that the column is installed at the proper depth and without mechanical strain.

Step 4: Perform a Blank Run or Analyze a Standard Test Mix

Diagnostic runs are valuable for identifying contamination and assessing column performance. Blank injections can reveal ghost peaks, while standard test mixtures provide insight into resolution, retention time accuracy, and peak symmetry.

Recommended action: Compare test results to the column’s original quality control report to detect performance degradation.

Step 5: Replace Suspected Faulty Components

If previous steps do not resolve the issue, begin systematically replacing components, starting with consumables.

Recommended action: Replace low-cost parts such as septa, liners, or O-rings before considering column or detector replacement. A logical, stepwise replacement approach ensures efficiency and prevents the unnecessary disposal of functional components.

By following these GC troubleshooting guides, common sources of error in gas chromatography can be isolated more effectively, leading to quicker resolutions and sustained instrument performance.

Preventive Maintenance Tips for GC Columns

Implementing routine maintenance procedures is essential for preserving the performance of gas chromatography (GC) systems and extending the operational lifespan of GC columns. The following best practices serve as foundational elements in effective column care.

Ensure Proper Column Storage

Columns not in active use should be stored with both ends securely capped to prevent contamination. Storage conditions must be clean, dry, and temperature controlled. Exposure to ambient moisture or air can lead to degradation of the stationary phase and compromise column longevity.

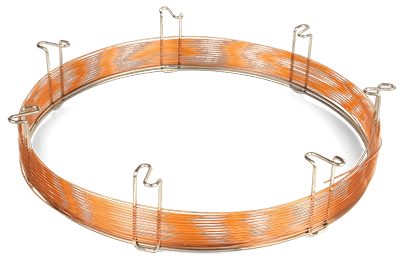

Utilize Guard Columns and Inlet Liners

Guard columns act as protective barriers, intercepting contaminants before they reach the analytical column. Similarly, inlet liners help to trap particulates and prevent the buildup of non-volatile sample residues within the system.

Regular replacement of guard columns and liners is recommended, especially when analyzing complex or heavily matrix-laden samples.

Perform Periodic Trimming

The column’s inlet end is most prone to contamination from sample residues and non-volatile materials. Routine trimming of a few centimeters can significantly restore performance and improve peak quality.

Conduct Regular Leak Checks and Replace Septa

Leaks can introduce oxygen and moisture—both of which are detrimental to column health. Routine leak detection using appropriate tools is advised, along with scheduled septa replacement.

Signs such as discoloration, cracking, or deformation of the septum after repeated injections indicate that replacement is due.

Use Clean Carrier Gas

The purity of the carrier gas plays a crucial role in protecting both the column and detector. It is imperative to use ultra-high purity gases equipped with moisture and hydrocarbon traps to prevent contamination.

Research, including work by Grob and Barry (2004), has demonstrated that gas cleanliness is especially important in trace-level and GC-MS applications, where even minor impurities can lead to significant analytical errors.

By following these preventive maintenance strategies, GC users can maintain stable performance, reduce unplanned downtime, and ensure consistent data quality across analyses.

When to Replace your GC Column

Recognizing the end of a GC column’s life is essential for maintaining data quality and system reliability. Performance trends often indicate when a column is near failure. Common signs include persistent peak tailing or broadening - even after trimming - along with inconsistent or shifting retention times.

A noticeable increase in baseline noise or bleed, reduced resolution despite maintenance, and recurring ghost peaks or unstable baselines are all indicators that the column is no longer performing optimally.

Physically, discoloration or damage to the inlet end of the column suggests contamination buildup, often caused by dirty samples or reactive compounds. While trimming can temporarily restore performance, repeated issues signal that full replacement is likely needed.

When selecting a new column, it is important to match the specifications - stationary phase, length, internal diameter, and film thickness - to maintain consistency. High-quality options like Zebron GC columns from Phenomenex offer reliable durability and performance across a wide range of applications, supported by comprehensive Zebron GC troubleshooting resources to help users optimize their results and resolve issues quickly.

FAQs

What are the most common gas chromatography problems?

Peak tailing, baseline drift, ghost peaks, poor resolution, and retention time shifts are common. These issues are typically caused by leaks, contamination, or aging components.

How do I know if my GC column is damaged?

If performance does not improve after maintenance or trimming, and issues like inconsistent retention times or excessive bleed persist, the column may be damaged.

How can I improve peak shape in GC analysis?

Check injection volume, trim the column, clean or replace liners, and use a column phase suited to the analytes. Avoid overloading and confirm there are no active sites.

What causes ghost peaks in GC?

Ghost peaks are typically caused by carryover, dirty inlet liners, or septum bleed. Contaminated solvents may also contribute.

Does polarity affect GC?

Yes, the polarity of the stationary phase influences analyte interaction and separation. Using the wrong polarity can result in poor resolution and overlapping peaks.