Advancements in Gas Chromatography Column Technology: Trends & Outlook

June 24, 2025

Author: Duilio Romanello

Gas chromatography (GC) remains a cornerstone analytical technique in fields ranging from environmental science to pharmaceuticals, driven by its precision in separating and analyzing complex mixtures. Central to its performance are GC columns, which have undergone significant advancements in recent decades. Innovations in stationary phase materials, column miniaturization, and efficiency have enhanced resolution, speed, sensitivity and applicability, enabling researchers to tackle increasingly complex analytical challenges.

Key Areas of Technological Advancements in Gas Chromatography (GC) Columns

In gas chromatography, analytes are vaporized and transported through a heated column by a carrier gas, where they are separated based on volatility and interactions with the stationary phase. Often considered the “heart” of the chromatograph, the GC column plays a critical role in determining separation efficiency, analysis speed, and method flexibility.

Recent advancements in GC sampling, column technology, and detection have broadened GC's applications across fields such as food science, clinical and forensic testing, metabolomics, and the petroleum industry. Innovations include enhanced column chemistries for improved selectivity and multidimensional separations for increased peak capacity. Key technological advancements in GC column design and configuration include:

Evolution from Packed to Capillary Columns

The evolution of column technology has been instrumental in the advancement of gas chromatography (GC). In its early days, GC relied on packed columns, which offered high retention factors and selectivity but came with drawbacks such as lower efficiency and the need for significantly higher inlet pressures.

A major breakthrough came with M.J.E. Golay’s introduction of capillary columns, which dramatically improved separation efficiency and resolution. Capillary columns quickly surpassed packed columns in performance, offering higher efficiency and greater peak capacity—advantages that made them ideal for complex analyses. While packed columns could handle larger sample volumes, their limitations in pressure tolerance and separation performance led to a gradual decline in their use.

Initially, capillary columns were made of glass and were prone to breakage. This changed in 1979 with the development of flexible fused-silica capillary columns coated with a protective polymer. These new columns, with thinner walls measuring about 40–45 μm, were both durable and flexible, greatly enhancing ease of use and expanding the range of GC applications.

Today, capillary columns dominate the field of gas chromatography, while packed columns account for less than 20% of the market.

Innovations in Stationary Phases

Early stationary phases were relatively simple, but improvements in coating technologies led to the development of chemically bonded and cross-linked phases. These improvements enhanced the thermal and chemical stability of the stationary phases.

With the advancements in gas chromatography, various cross-linking methods were employed, including free-radical reactions, thermal and radiation techniques, and condensation using multifunctional binders.

Additional stationary phases based on adsorption were also developed during this period, leading to porous layer open tubular (PLOT) columns that proved effective for analyzing volatile compounds. To improve the stability of the wall coated open tubular (WCOT) phases, researchers modified the polysiloxane backbone with stabilizing groups, resulting in more durable phases.

These innovations enabled selective phase development for challenging applications, such as analyzing acids, bases, chiral compounds, and high-temperature samples, greatly expanding the capabilities of gas chromatography.

Column Dimension Optimization

Understanding how column length, internal diameter, and film thickness affect resolution is key to optimize gas chromatography methods.

- Doubling the column length increases efficiency and resolution but also lengthens analysis time and raises costs.

- Reducing the column’s internal diameter improves resolution and efficiency but increases head pressure, while larger diameters offer greater capacity.

- Film thickness influences retention and resolution: thicker films retain volatile compounds better and increase inertness but generate less efficiency and may cause more bleed and lower the maximum usable temperature.

Choosing the right combination of these parameters helps achieve better separation, particularly when stationary phase or temperature adjustments alone are insufficient.

Multidimensional Gas Chromatography (MDGC)

In highly complex samples, traditional one-dimensional gas chromatography (1D-GC) struggles due to limited peak capacity, but adding a second separation dimension greatly enhances separation by exploiting differences like polarity.

Multidimensional gas chromatography (MDGC) involves the sequential use of two or more chromatographic separations to isolate and identify volatile and semi-volatile compounds in complex mixtures, offering higher resolution than single-column techniques.

Most MDGC systems use two columns and are categorized as either heart cutting 2-D GC or comprehensive two-dimensional GC (GC×GC), which differ in implementation despite using similar equipment. Although MDGC has existed for over 50 years, recent advancements have significantly expanded its applications and improved analytical performance.

A typical column set in multidimensional gas chromatography includes:

- The first-dimension (1D) column is typically 15–30 meters long with an inner diameter of 0.25–0.32 mm, providing the primary separation.

- The second-dimension (2D) column is much shorter, usually 0.5–2 meters long with a narrow 0.1 mm inner diameter, and performs rapid separation within a few seconds

Using complementary stationary phases allows for a significant (~10-fold) increase in peak capacity and enables selective targeting of specific analytes, such as PCBs based on ring substitution. Additionally, multi dimensional gas chromatography (MDGC) provides structured chromatograms that help distinguish compound classes and infer structural information, even without reference standards or strong library matches.

Column Temperature Control

In the early days of GC, several heating methods were explored, including vapor baths, oil baths, and air baths, all relying on fluid convection. Vapor baths offered limited temperature ranges and posed safety hazards, while oil baths allowed broader ranges but were messy and risked damaging columns.

Air bath ovens were introduced in the 1950s and became the standard by the 1960s in conventional GC systems due to their cleanliness, simplicity, reliability, wide temperature capability and uniform heating of different column types. However, their slow heating rates, high power consumption, and bulky size make them unsuitable for fast separations and portable instruments.

Radiation-based heating methods, such as microwave and infrared ovens, provided faster heating and lower power use but faced challenges with uniform heating, limiting their widespread adoption.

Resistive heating, which uses compact, low thermal mass heaters to directly conduct heat to the column, addresses these limitations and is re-emerging as a promising alternative. This method is especially advantageous for developing portable GC systems such as lab-on-a-chip devices and achieving high-speed separations, even in conventional setups.

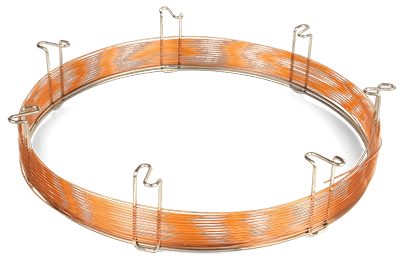

The recent development of low thermal mass (LTM) column modules has been a breakthrough in gas chromatography evolution. It involves wrapping the capillary column with a heating element and insulation so it can be heated directly rather than heating the entire oven chamber. This technology allows extremely high-speed rates of up to 1800 °C per minute and cooling from 350 °C to 35 °C in under 2 minutes. It also supports independent temperature control for up to four column modules on a single GC platform.

Data Handling and Automation

With the emerging trend in GC, comprehensive GC×GC chromatography has become a powerful tool for both targeted and nontargeted analyses. However, the complexity of GC×GC data presents significant challenges for streamlined processing, often requiring multiple disconnected tools.

As a result, data handling after GC×GC– time of flight mass spectroscopy (TOF-MS) analysis is often performed using a combination of instrument software for initial processing and additional external tools. A novel approach addresses this issue by utilizing an underused interface within commercial software to incorporate free and open-source tools into a unified workflow.

This allows for customizable, automated data processing within a single environment. The concept has been demonstrated by performing retention time alignment in a large-scale GC×GC metabolomics dataset using both bespoke and published algorithms. The alignment reduced retention time variability from 8% and 16% coefficient of variation (CV) to less than 1% and 2%, enhancing workflow efficiency, automation, and interconnectivity with broader informatics platforms.

Various free and open-source tools have been developed to process GC data, offering cost-effective, customizable alternatives that support multiple file types and can be modified by users. However, these tools often lack user-friendly interfaces, are narrowly focused on specific tasks, and require analysts to assemble complex workflows across multiple platforms and programming environments. Thus, many users rely on hybrid workflows that combine commercial software for core functions with open-source tools for advanced processing, leading to fragmented, time-consuming processes that are difficult to reproduce and standardize.

Addressing Industry Challenges with Advanced GC Columns

Each new advancement in GC column technology brings benefits and fresh challenges.

- GC×GC can be applied to most samples suitable for traditional GC, but limitations arise with extremely volatile or high-boiling compounds due to modulation constraints.

- Additionally, there is no defined threshold for the number of compounds in a sample that mandates the use of GC×GC or MDGC, making its application somewhat case-dependent.

- Another challenge the industry faced was the global helium shortage, which raised costs and uncertainty for GC users (since helium has long been the preferred carrier gas). Advanced column techniques often rely on high carrier gas flow rates or pressures, exacerbating helium supply concerns. The solution emerging is a shift toward alternative carrier gases like hydrogen and nitrogen.

- Longer and narrower columns are more expensive due to the added complexity and materials needed for their manufacture.

Future Trends and Phenomenex’s Vision

At Phenomenex, we envision a future where innovations in column design go hand in hand with breakthroughs in detection technologies.

Our team has highlighted how advancements in mass spectrometry - such as high-resolution quadrupole, ion trap, and time-of-flight analyzers - are elevating GC’s sensitivity and speed. These tools enable ultrafast GC with shorter columns and precise temperature control, enhancing throughput without sacrificing performance.

We also anticipate deeper integration of GC with other analytical platforms. A prime example is the growing use of GC-MS in clinical diagnostics. Where GC was once uncommon, it now plays a key role in analyzing biomarkers in blood and urine - thanks to our highly efficient columns and the precision of modern mass spectrometry. This synergy is unlocking exciting new possibilities for GC in medical and high-sensitivity applications.

Explore the full range of GC columns from Phenomenex, including specialized solutions for high-temperature, low-bleed, and complex sample analyses.

Frequently Asked Questions

What are the recent advancements in gas chromatography columns?

Recent advancements in gas chromatography columns focus on improving efficiency and resolution. The introduction of narrower and shorter columns has accelerated analysis times, while enhanced stationary phases provide better selectivity and thermal stability. Additionally, column designs have evolved to support high-throughput and miniaturized systems, making them more adaptable to modern analytical demands.

Are high-temperature GC columns better than standard columns?

High-temperature GC columns are better suited for analyzing compounds with high boiling points or thermal stability. They offer improved durability and performance under extreme conditions compared to standard columns. However, they may not be necessary for routine analyses involving volatile or low-boiling compounds.

How do modern GC columns improve analytical performance?

Modern GC columns improve analytical performance by offering faster separation, higher resolution, and better sensitivity. They achieve this through advanced materials, narrower internal diameters, and optimized stationary phases.